Just one container can produce 110g of protein every 10 days. A single 3m by 3m wall can generate 1.7kg of high quality animal protein every 10 days. Just imagine what a whole room or shed can do.

The may have read the media that Insects will feed the masses. Unfortunately this is more hype than reality. For the greater part, breeding insects is labor intensive, requires high capital outlay and requires specialized knowledge to prevent pests/diseases and to optomize productivity. For much of the developed would this is out of reach for the every day family or farmer.

After 15 years of breeding insects and working as a consultant for insect breeders around the world, we have developed a cricket breeding system that over comes the above issues. Below we outline the issues that breeding crickets have historically had, and how our “single container system” solves these issues. Welcome to the “Kvassay Cricket Container”. Our real life solution to feed the masses.

Below we discuss the following:

Who are we....and our 15 years Insect Breeding Experience

Breedinginsects.com is a website developed by Zega Enterprises that provides comprehensive training and consultancy service for the insect breeding industry. Zega Enterprises is a sole trader busines from Australia that was set up and run by Glenn Kvassay. Glenn is a passionate and qualified biologist that specializes in insect production systems and other sustainable food sources (aquaponic, moringa, plankton and duck weed systems).

We have been breeding and training people on how to breed insects for over 14 years to both small scale hobbyist or large scale commercial breeders. Below are the key products and services we provide:

- Training Resources– We have a comprehensive online and practical training resources to breed Crickets, Mealworms, Cockroaches and Soldier Fly Larvae. This includes online books, videos, training courses and articles. Our Cricket, Mealworm and Cockroach books are the most comprehensive in the world.

- Partnerships– We have established partnerships around the world to help start up and improve the productivity of established insect businesses. We provide advice for free and in return we ask they provide their learnings, costings, income and production rates. For start-up businesses we provide, planning, cost estimates, training and mentoring. For established businesses we advise on how to improve efficiency and solve problems.

- Consultancy Services– We provide consultancy services for start up and established insect breeding business that provide the same advice outline in the partnership section above.

- Research- Our mobile insect farm (20-foot caravan) is used as a research facility to benchmark insect production rates and methods. In our partnership program we also run benchmarking and experiments which we add to our online b

- ooks as a resource to insect breeders. By benchmarking expenses, building costs, energy, production rates etc we provide confidence to insect breeders to set up a farm.

- Product Development (New Breeding Methods): We have developed and benchmarked our own proprietary insect methods which we very efficient at producing high quality protein. We are very confident this new method could be a game changer for providing food to developing countries by making them into flat pack versions.

What are the Problems Breeding Crickets

The problem however is that breeding insects is a business of hard knocks which has many pitfalls that most farmers either don’t know about, or greatly underestimate. Over the last 14 years we have experienced firsthand the issues farmers face and in more recent years the consultancy has helped farms around the world tackle issues we have not experienced ourselves. This is across the board both for both small and large-scale production. Some learnings we have had over the years include:

- Mites, moths and spiders devastated our mealworm farm

- Vinegar flies, ants, spiders and geckoes devastated our cricket farm

- After 4 years of breeding crickets using a standard method, we learnt 4 key factors which more than doubled production rates.

- We tried to breed mealworms in a warm environment without climate control which had very low productivity. We chose a different species or added climate control and increased output two to three times.

Below are the key barriers we see insect farmers face:

- The other reason many insect farms don’t become profitable is that there is a very large learning curve involved. To make this worse there is very little quality information on the net which shows people how to breed insects as a business using efficient methods. It has taken us 14 years to develop effective methods to breed insects consistently, largely from years of trial and error.

- Most start up farms will go through this unprofitable stage and most will give up if not given the right advice and guidance. We aim to skip this step and take them to profitability by teaching them best practice and providing the with a multitude of tools and knowledge to move past this stage.

- One key barrier to the edible insect industry is connecting breeders, wholesalers, retailers, clients with products and services.

It is a simple fact that if you don’t have the right training you will hit a wall and probably fail, or it will take you years to become successful. Furthermore, even if you get the right training you need mentoring to make sure you keep on track. This is the main reason why insects to date have not been widely adopted to its full potential and not adopted on scale by many poor communities.

The businesses that succeed typically do not share their secrets to keep their competitive advantage and a to increase their client base.

How the "Kvassay Cricket Container" solves many of these issues

Over the last 14 years we have tried most of the conventional methods of breeding insects and developed our own proprietary methods. One of the more difficult species to breed consistently is crickets. Despite this difficulty, they are also one of the most appealing species for human consumption as they have less of the “yuck factor” that other species have (ie worms and cockroaches).

Over the last 14 years we have tried most of the conventional methods of breeding insects and developed our own proprietary methods. One of the more difficult species to breed consistently is crickets. Despite this difficulty, they are also one of the most appealing species for human consumption as they have less of the “yuck factor” that other species have (ie worms and cockroaches).

We have developed a proprietary cricket breeding method which has the following benefits:

- Very low maintenance– Requires much less than conventional methods. Each container only needs just a few minutes maintenance every 10 days. High maintenance is the number one reason people don’t succeed in breeding crickets. This greatly reduces the labor costs and can be done by anyone (including women)

- Very productive- has a very high output that is higher than most commercial insect farms that use high tech climate control and high labor costs. This high production rate is achieved with very low-tech climate control (ie just a heat pad, no climate control room required).

- Low Tech- Most productive cricket breeding systems require high tech climate control and high operator skill level. Our system is low tech and is able to be run by any person no matter what their technical capabilities. This is important in rural areas in developing nations.

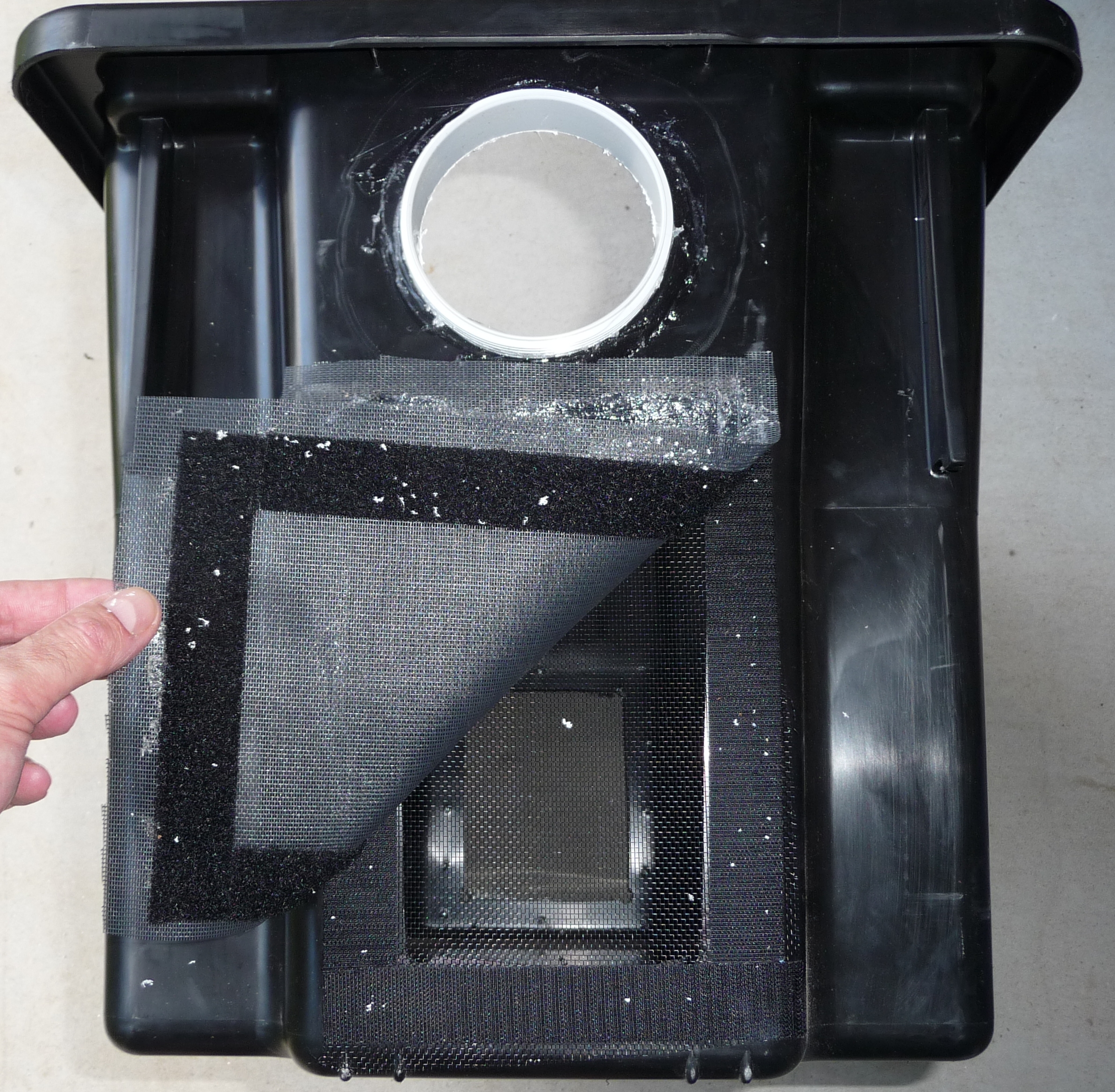

- Very Robust: Most cricket farms fail due to the need to manage multiple factors like heat, humidity, pests, food and hydration. They also invariable get a variety of pests such as vinegar flies, mites, ants, spiders. Our system has automated food and water dispensers, manages heat and humidity with smart design. This makes the management very minimal and the system is very robust.

- Low Cost: Once the initial design costs have been covered, we hope to produce a very low cost flat pack that can be sold to farmers at cost price or subsidies to poor communities.

- Utilizes Waste: Crickets can be fed both pellet food or agriculture or residential waste.

Does it work: I have benchmarked this system for around 12 months having recorded inputs, outputs, electricity consumption, climate and production rates. This low tech outperforms high tech systems and is so easy to operate. After 14 years of breeding crickets using multiple methods I have never seen a method work so well.

It has huge potential to develop high quality animal protein, with minimal effort. It is my strong belief this method must be developed as a potential food source for people.

Development: Now I am confident in the systems operation and production rates; I wish to develop this method as a flat pack version. This would enable the cricket containers to be shipped worldwide (currently cricket containers are very large, and delivery is expensive). Funds are required to have an industrial designer develop a plan to build the system as a flat pack and at the lowest unit cost.

How Does our Container Work

Outline the production rate and convert this to meals which can be produced.

Identify the Uses and Opportunities for this System

What is Required to make this a Reality and Feed families.

High tech facilities such as this one can produce large amounts of crickets in a controlled and stable environment. A high tech facility is out of reach for many people in rural areas that do not have significant resources, training and skills required to succeed. Our single container system takes out all the technology, expense and expertise. We rely on a clever design to do all this….and it does.