This manual covers two cricket breeding systems for Small Scale production and one method for Commercial production. Below are the pros and cons of each method and advice on which method is best for you.

Note: The size of the container will determine how many crickets it can house. You can choose any size container you like, however the figures provided below are based on 18.5 gallons or 25.59 inches by 16.53 by 15.75 (70L, 65cm long, 42cm wide and 40cm high).

Tip: Insects are high in fats and energy and overfeeding often results in animals (pet reptiles/amphibian, aquaponic fish) becoming overweight or malnourished. Be sure to familiarize yourself with the correct eating requirements of the species you are feeding. For example, a balanced diet for a bearded dragon requires alternating feeds with fresh fruit/vegetables, meats (with supplements), live insects and occasional fasting. For More details refer to Chapter 19- Reptile Husbandry. Once you know how often your animal requires insects, you can estimate how many crickets you need per week.

Feature

Standard Cricket Breeding Method

Substrate Cricket Breeding Method

Batch Cricket Breeding Method

Used for:

- Small Scale/Hobbyist

- Most common method promoted on the internet.

- Small Scale/Hobbyist

- Small Scale Commercial

- This method developed by ourselves.

- Commercial

- Commonly used Commercially

- Where you want to produce more than 1200 large crickets per month, the Batch Breeding System is recommended.

Advantages:

- Very easy to build and can get you breeding crickets with little effort.

- Well suited to someone who doesn’t want to do a lot of DIY building.

- Is a productive system, with low maintenance. As large crickets are removed they are quickly replaced with a plentiful supply of pinheads generated from the large surface area of the substrate.

- It is a simpler system that does not require as many containers or components as required by the batch system.

- Micro flies are not usually a problem as the large crickets eat the maggots that lay their eggs in soil substrate.

- Improved hygiene and reduced maintenance. The vinyl floor of a substrate system prevents moisture from making direct contact with dry and wet food (described above), making it last longer and reducing fermentation and fungal issues.

- As each container has separate age groups, there is minimal cannibalism. This results in greater productivity.

- Separate age groups of uniform size is what clients want.

Disadvantages:

- Is relatively high maintenance which requires daily spraying. Over time many people tire of this and reduce the frequency of spraying, and the the system becomes less reliable.

- Extra care is needed to maintain the right humidity levels within the container which caters for both adults and pinheads. As pinheads and adults ideally require different humidity levels, having a single humidity level will be a compromise.

- As all age groups are housed in the same container pinheads and small crickets will be eaten by larger crickets. This will reduce the productivity of the system. This can be reduced by placing lots of hiding spots for small crickets.

- If you want less maintenance and higher output consider the Substrate Breeding system.

- As a “young adult cricket” (with a shelf life of around a 4-6 weeks) is the same size as an “old adult cricket” (with a shelf life of a couple of days) both sizes will be collected when sorting by size. This becomes a problem when a client purchases the crickets and they die before their next pick up (most clients will purchase crickets every 2-3 weeks).

- As crickets are a mixed age group, extra filtering is required to sell them to clients who want a particular size.

- As containers contain substrate they can be heavy and difficult to handle. Containers stored on high shelving, may be awkward to lower to bench height for maintenance activities. This can result in food/water containers tipping over and difficulty in handling a stacked colony. This system is best suited to benches at waist high or lower.

The higher production rate comes at the extra maintenance such as daily spraying of breeding trays, collecting pinheads from the incubation chamber and moving them to different containers.

Production Rate:

- As this system requires the breeder to manage heat and humidity, production can vary depending on breeder skill level.

- Same as the Substrate system where heat and humidity are regularly maintained.

- Each substrate breeding container will generate approximately 1 pet store container of crickets per week (approximately 33 large crickets/container) using heat pads. if a heated room is used the output can be increased to 1.5 containers/week/container. The advantage of this system is that it is low maintenance and does not require spraying or separating crickets from one container to another.

- The waste wet food generated from an average family (two adults, two kids) can produce enough crickets to support 4 substrate breeding containers. Additional containers will require wet food supplementation. Four containers will feed approximately 3 to 8 adult bearded dragons (depending on feeding regime i.e. balanced diet or 100% insects).

- More containers can be added as required until you reach 12 pet bought containers of crickets per week (approximately 400 large crickets/week). This equates to approximately 1200 large crickets/month. This equates to If you require larger quantities of crickets, then we recommend using a Batch Breeding System.

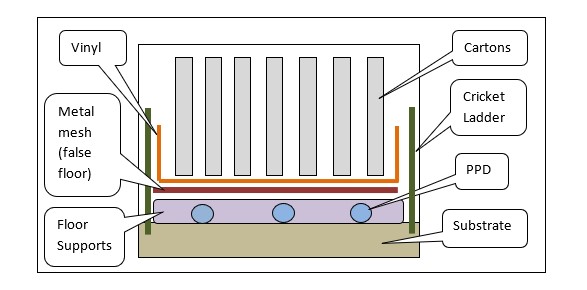

- Further details of this system including advantages and disadvantages are outline in Chapter 9.0 (Zega Substrate Breeding System).

- This system is more productive, producing more than 3 times the number of crickets per breeding container than the Substrate Breeding System. Six containers produce approximately 700-1400 large crickets per week depending on your heating system (700-heat pads, 1400-heated room), however it is more labor intensive, involves more components and needs to be actively managed.